Ultralight floor heating board

Our high-performance floor heating insulation improves heat-up times, spreads warmth quickly and is easier than ever to install.

Helps reduce energy usage

![]() Save up to 25% per year on energy costs.

Save up to 25% per year on energy costs.

Spreads heat better

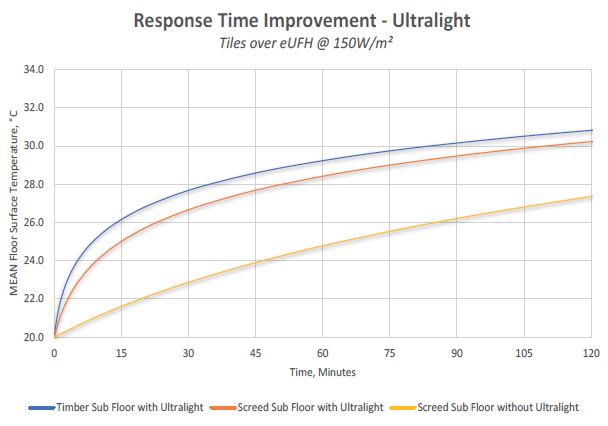

![]() 50% more even heating and 30% faster heat up times than standard boards

50% more even heating and 30% faster heat up times than standard boards

Built-in decoupling layer

![]() Helps protect floor tile damage caused by subfloor movement

Helps protect floor tile damage caused by subfloor movement

Do I need insulation boards?

Many people wonder if it is worth insulating under their floors and the answer is that yes, it definitely is. Insulation boards are ideal for use with electric underfloor heating as they prevent the heat from the heating system escaping downwards to the subfloor. The Warmup Ultralight™ Insulation Boards do not let the heat pass through from the heater to the subfloor. Therefore the heat gets pushed upwards, onto the floor surface where you want the heat to go. It is recommended to always carry out a heat loss calculation if you are considering buying an electric underfloor heating system to understand how well your house is currently insulated and how big the heat loss is in your home.

Insulation boards always improve the efficiency of your underfloor heating system by allowing a quicker heat up time, when no heat is getting wasted by going downwards away from the floor surface.

How do Ultralight™ insulation boards work?

Ultralight™ is a specialized composite board for floor heating applications. The boards multi-layer design with aluminium, non-woven fleece, and insulation works to achieve 3-in-1 benefits: insulating, heat spreading, and decoupling.

The rapid thermal response promoted by the insulation and diffusion layer allows the flooring to heat up faster, resulting in a more energy-efficient and comfortable heated floor.

With no cement coating, Ultralight is also more flexible than other insulation boards and can be easily cut to requirements with no risk of dust.

How to install Ultralight™ insulation board

Ultralight™ installs dust-free in 4 simple steps and the lightweight composite design makes it easier to cut curves and complex shapes without dulling knife blades, compared with cement-based backer boards.

1. Clean and dry a level surface

2. Prime with a solvent-free primer

3. Trowel out 1/4″ of flexible, cement-based adhesive

4. Lay boards on fresh grooves with staggered joints.

| Size | 800 mm (W) x 1200 mm (L) area 0,96 m² |

| Weight | 1,1 kg |

| Thermal resistance R-Value | 0,111 m²K/W |

| Compressive strength | 220 kPa |

| Thermal conductivity | 0,054 W/mK |

| Reaction to fire | Euroclass E |

| Crack resistance (anti-fracture / decoupling) | ≥ 1/8″ => high performance |

| Warranty | 10 years |